|

Pequest Trout Hatchery Updates Its Flow Control Monitoring System

by

Jeff Matthews, Hatchery Superintendent

Clint Decker, Crew Supervisor - Building Maintenance Programs

February, 2007

Moving Water

|

At

the Pequest Trout

Hatchery, flowing water is life! Clean, moving, cold water

is essential to the success of a trout rearing facility. Six

artesian wells provide the hatchery with up to seven thousand

gallons of water per minute. Remaining at 52 degrees Fahrenheit

year round, and capable of maintaining a continuous flow, the

water supply is a critical factor in propagation and maintaining

a trout production cycle.

The

hatchery sits in the Pequest River Valley over the Basin Aquifer/Valley and Ridge Sedimentary Units, a water-logged limestone formation. The topography

serves as a huge natural funnel, channelling precipitation trapped

between granite mountains on both sides to the valley floor,

replenishing the aquifer.

|

Water

flows through the hatchery in the upper aerator building.

Water

flows through the hatchery in the upper aerator building.

Click

to enlarge |

The

Hatchery Water Flow

The

hatchery's water flow begins with the six wells sunk deep into the

aquifer. Powerful vertical turbine pumps, some as large as fifty horsepower,

bring water to the surface. It then travels through large pipes to

flow meters in the well houses.

|

|

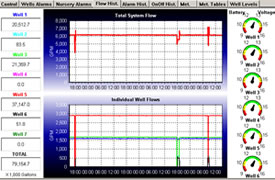

Measured

in gallons per minute (GPM), the water is sent through an underground

manifold, eventually arriving at the Upper Aerator Building.

Here the water spills out and goes through tanks filled with

"biorings" for aeration.

Biorings

are small cylindrical plastic structures that allow oxygen to

be induced into the low-oxygen ground water. After passing through

and being aerated by the biorings, the water is piped underground

to a distribution box and sent to the four double upper raceways.

|

|

|

After

traveling the length of those raceways, the water flows to the

lower aerator building where the aeration process is repeated.

The water flows through the four double lower raceways, to the

broodstock raceway, and then through a sluiceway into the Pequest

River.

From

September to the end of May a portion of the water is sent to

the Nursery Building. Here eggs are incubated and newly hatched

fry and fingerlings are raised. Most of the water in the nursery

is recycled, flowing from the upper aerator to a wall tank that

runs along each side of the building and then into individual

fry tanks. From the tanks the water is collected and pumped back

to the aeration building and out to the raceways.

|

|

The water at Pequest must flow continually, twenty-four hours a day,

year round, without any interruptions. So what makes this happen reliably

and efficiently? Large motorized pumps and...a new flow monitoring control

system!

Out

With the Old!!!

|

|

The

hatchery's old flow control and monitoring system was divided

into two systems. Three well houses were hardwired directly

to the Nursery Building, and the other three used touch-tone

telemetry technology over telephone lines. These all connected

to an alarm panel in the nursery and were integrated into a

system that would monitor all parameters of the system. The

three wells that were hardwired (2, 3, and 4) are close enough

to the nursery building to be run in conduit underground, but

wells 1, 5, and 6 are much farther away - more than a mile in

the case of Well 5.

At the time of the hatchery's construction tone telemetry was

state of the art. It takes a command, converts it into tones

and transmits them over a phone line. A receiver hears that

tone, recognizes it, and performs the task that was asked of

it. This worked well for many years. However, like anything

in the technology field it became outdated and obsolete over

time. The company that made the equipment went out of business,

making repairs or obtaining replacement parts almost impossible.

There also was an ongoing concern that if a tree fell on the

telephone lines it could take out multiple wells, endangering

the hatchery's fish.

Although

Wells 2, 3, and 4 are hardwired, they are still a distance from

the control center (Well 2 is the closest of the group and still

over 1000 feet away). This created problems, particularly due

to the underground wiring being outdated and vulnerable to moisture.

The

issue became determining the kind of system which would do the

best job. Considerable time was spent investigating alternatives

and options. It also included researching the best way to solve

problem issues and provide a system that would stand the test

of time.

|

The

Solution

The solution is a wireless system using spread spectrum radio technology.

This is the same technology the military uses on the battlefield to

transmit critical data. There are tremendous benefits, first being

the elimination of maintenance on telephone lines or concern over

water in the underground wiring system. After some research, Campbell

Scientific was contacted because of their specialization in aquaculture

facilities all over the world. After a consultation with their representative,

project specifications were developed and bids requested. The contract

was awarded to BLU

DOT INC. and work began in the fall of 2005.

|

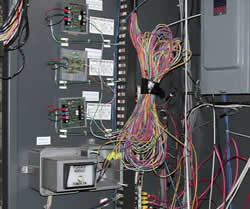

The

first step was a complete evaluation of the old system. A review

of original plans and tracing existing wires was completed.

Decisions were made on what was still useful and what had to

be removed. After the old wiring was removed and obsolete components

removed from the control panels, the new equipment was installed

along side the existing components. The old system remained

partially functional while the installation of the new equipment

was being completed.

The

new system starts with a "spread

spectrum" radio and antenna connected to a data logger

at each location. The loggers in turn hook up to corresponding

devices. These control each well pump, monitor alarm parameters

and show pump run status. Also hooked up to the data loggers

are the flow meters in each well house.

|

|

The

state of backup diesels in well houses 1, 2, and 5 is also monitored.

These diesels power the pump in the event of a power failure. Wells

3 and 4 can be operated during a power failure with a backup generator,

also monitored by the new system. All data is transmitted back to

the Nursery Building where it can be monitored during regular and

emergency situations.

|

|

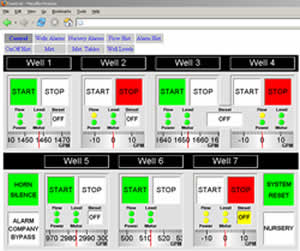

The

user interface with the new system is a 15" touch screen

mounted in the Nursery Building. From this panel the entire

operation of control and command of the wells takes place. The

panel has five different screens: Control, Well Alarms, Nursery,

Alarm History, and Weather. Each screen has a purpose:

- The

Control

Screen manages the operation of the electric pump

motors.

- The

Well

Alarm Screen controls all the enabling and disabling

of each alarm parameter.

- The

Nursery

Screen displays and controls the status of all nursery

water systems (wall tanks, pump backs and incubator flows).

It will also contains the Totalizer, measuring GPM for each

well and total hatchery flow.

- The

Alarm

History Screen records every event with a time stamp,

making troubleshooting any problem much easier than in the

past.

- The

Weather

Screen displays the current outside conditions.

|

All

monitoring is done in the nursery and at two remote computers within

the hatchery complex. The system is continuously monitored. Any alarm

condition sets off an external siren on the raceways and notifies the

alarm monitoring company. Staff is notified and immediately reports

to the monitoring stations to evaluate the emergency.

|

This

system is PC-based (an industrial computer using Windows XP),

unlike our old system, and has been integrated into our local

computer network. This is another benefit of this system, allowing

us to connect the monitor computer to our network and have the

system running on computers in two different buildings. This

redundancy within the system allows for control and monitoring

in an emergency condition should one of the links in the system

fail to work.

The

radios in the well houses and the one in the nursery (which

is the base station) constantly communicate, sending packets

of data every few seconds and continually updating information.

The system also has an alarm should the base station lose contact

with one of the satellites for any length of time.

|

|

|

|

Another

benefit of the new system is the solution to a problem in Well

3. Well 3 is in an underground vault in front of the main building.

With no place to easily mount an antenna, it was suggested by

BLU DOT INC. that a ten-foot meteorological tower, with the

transmitting antenna, be installed.

The

weather station automatically tracks precipitation and cross-references

it to our well's water levels. The station sends the weather-related

data to the nursery for use by the staff, and a weather database

has been developed to monitor conditions in the Pequest Valley.

(See Weather

Screen display.)

|

|

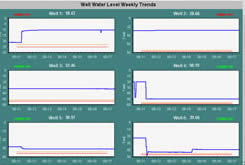

Pressure

transducer probes have been installed in the wells to monitor

and record well water levels. This is invaluable to protect

the huge investment in the vertical turbine pumps and motors.

Severe damage could occur if water levels are too low in the

wells.

The

system sends warning alarms when water levels are getting too

low, and adjustments are made to raise the water level in the

affected well. If the condition gets too severe, the motor will

shut down.

|

|

Other

benefits are that the radios have a very low current draw, meaning they

can stand alone for almost thirty hours without line voltage, running

off a 12-volt rechargeable battery. Valuable information will not be

lost and monitoring will continue during any power outage.

|

|

Overall,

the new system to date has been working without a problem. It

also is expandable and can be upgraded on an as-needed basis.

When well 7 is completed and comes online it will be very easy

to add it to the system.

Dealing

with a live product - in this case trout - there is no room

for mechanical malfunctions. The new flow control and monitoring

system has brought the hatchery back to being one of the most

modern and efficient trout hatcheries in the nation.

|

|